Division

HVAC

Market trends

In the reporting year, the HVAC Division achieved revenue amounting to CHF 529.1 million. This represents a decrease of –4.6% in comparison to the previous year (CHF 554.7 million). Adjusted for currency effects, however, the revenue closed at –0.4%, just slightly below the previous year as well. However, as a result of immediately implemented cost-cutting measures and a variable cost structure, the division succeeded in improving the EBITDA margin to >11%. Without one-time effects, EBITDA amounted to CHF 59.6 million and was thus 1.0% above the figure for the previous year (CHF 59.0 million). EBITDA incl. one-time effects amounted to CHF 59.2 million, which corresponds to an increase of 14.8% (previous year: CHF 51.6 million). EBIT without one-time effects was CHF 30.0 million, –6.5% bellow the previous year's figure of CHF 32.1 million, but EBIT with one-time effects closed with CHF 29.6 million, 30.3% above the previous year (CHF 22.7 million).

The main markets of the HVAC Division were affected to varying degrees by the COVID-19 pandemic. While construction activity in Germany and Switzerland was only marginally affected, the markets in Italy, Spain, France, Belgium and Russia in particular were hit hard during the first wave of the pandemic due to temporary construction site closures. In addition, in some countries such as Italy and Russia, temporary plant closures were ordered by the authorities during this period, interrupting supply chains to a certain extent. However, thanks to special permits from the authorities due to recognised system relevance, the affected production plants were allowed to resume the corresponding production within a short period of time. This circumstance, together with the implementation of consistent measures, flexibility, and the commitment of the employees, meant that the division was already able to resolve or stabilise the supply situation within a few weeks. The already constant shortage of skilled workers worsened in the reporting year, as the mobility of cross-border workers was considerably restricted in some cases.

Despite a temporary plant closure, the HVAC Division was able to celebrate the production of its 100 000th steel panel radiator in July 2020 and its 200 000th in November 2020 at its new production plant in Stupino (RUS). Even though the planned commissioning of the installed second welding line could not be realised in the reporting year due to the closure of the national border caused by COVID-19, the location nevertheless already ensures a more intensive market cultivation in the entire CIS region. In addition, the production plant in Dilsen (BE) was able to increase its production capacity for underfloor heating pipes significantly, and the production plant in Corbetta (I) was able to put a new painting line into operation. Overall, the division improved its competitiveness through continuous optimisations and investments in its efficient, highly integrated production network.

Products, technology, and innovation

The HVAC Division is consistently pursing its strategy of being an innovative provider of systems and components that use water, air, and electricity to exchange heat for all types of buildings and application areas, both for the new construction and renovation markets.

In the radiator segment, for example, a new bathroom radiator with an age-appropriate operating solution for the thermostatic head and the introduction of an aesthetic yet functional mirror front for infrared radiators in the premium segment have expanded the product range since the beginning of 2020. More than 75 million Kermi steel panel radiators installed worldwide underscore the sustainable success of the existing portfolio.

In the area of surface heating, the division specifically addressed the requirements of the housing industry in the reporting year with expanded performance classes for the home station, thereby ensuring efficient heat distribution combined with hygienic domestic hot water heating.

In addition, a new layered buffer storage tank with significant efficiency advantages was added to the product range for heat storage. Its unique modular principle covers a wide range of variants and makes it easier to install the entire heating system around the heat pump.

In the ventilation segment, the range was already expanded at the beginning of 2020 to include a particularly space-saving, very quiet central ventilation unit with a high heat recovery that meets the performance requirements of larger residential units as well as the renovation market. Due to the COVID-19 pandemic, the already existing trend towards controlled ventilation systems for improved indoor air quality has rapidly gained in importance, which has led to a significant increase in demand for indoor air filtration products for health protection from the production plant in Magenta (I). Especially for the patented "Crystall®" electrostatic filter, which can be used in fan coils, in ceiling cassettes, in the new air purification units "Sky Safe" and "Crystall Round", as well as in ventilation systems for commercial, industrial, and public buildings regardless of the brand, Sabiana had to expand its production capacity with a second production line at short notice in order to meet the increased customer demand. It was also possible to transfer the successful model of these certified product solutions to the portfolio of other brands in the division.

Due to the COVID-19 pandemic, almost no national or international trade fairs took place, which meant that an important element for the market launch of new products and for customer relations was missing in the reporting year. As face-to-face customer visits were not an option at times, digital communication media became fundamentally more important. However, the division is already optimally positioned in the field of digital marketing. Its offer includes a variety of digital tools specially tailored to the respective customer group, from webinars on various topics (e.g. indoor air quality) to individualised homepages of the individual brands to special apps in augmented reality format as product configurators for selecting the right product with an integrated ordering function.

However, the HVAC digitisation strategy is not limited to only the sales interface to the customer but also extends across the entire value-added chain from product development and production to the after-sales area. An important project in this context is the implementation of an integrated product information management (PIM) for quick access to comprehensive product data material in the BIM standard to improve customer satisfaction further.

The continuous optimisation of the different brand-specific product portfolios is one of the strategic goals of the HVAC Division and was largely advanced according to plan in the reporting year. However, not only did new developments, for example, in the area of residential ventilation, expand the local product ranges in this context, but the integrated production network was also used to expand the respective product ranges through cross-selling. For example, Vasco in Benelux closed the gap to become a full-range supplier by launching a heat pump produced in the Czech production plant on the market.

Other important projects were also successfully completed or advanced, such as a new painting line at the Sabiana production plant in Corbetta (I) to optimise the production efficiency and painting quality, the modernisation of the tubular radiator production at the production plant in Stříbro (CZ), the automation of the steel panel radiator production at the production plant in Plattling (D), as well as the integration of logistics for the Vasco and Kermi brands in Poland.

Overall, the division was able to deliver almost fully throughout the entire period of the COVID-19 pandemic, despite its Europe-wide market presence, due to production close to customers and local warehouses.

Outlook

The current COVID-19 pandemic makes forecasts for 2021 difficult. On the one hand, there are very positive basic trends, such as government subsidy programmes for climate protection investments in building technology, low interest rates on loans, and a continued high demand for housing in the context of urbanisation. On the other hand, the pandemic-related uncertainty in the economy will lead to an at least temporary reluctance to make investments in commercial and industrial construction projects.

Due to its wide sales market presence, its high process efficiency in production and administration, continuous innovations, as well as its strategic positioning as a full-range HVAC supplier for residential and non-residential construction for all applications in both new construction and renovation, the division is optimally positioned to continue to grow profitably.

Indoor air quality

The "Crystall®" electrostatic filter from Sabiana for improving indoor air quality fundamentally gained importance with the onset of the COVID-19 pandemic. Numerous reference projects in Italy were won, including the BNP Paribas towers in Rome and Milan, the headquarters and many branches of Poste Italiana, as well as Fiumicino Airport in Rome. Arbonia and Prolux were also able to win their first projects immediately after the filter began to be marketed in Switzerland and Germany.

New Prolux website

As a basis for future digitisation projects, the new Prolux website offers quick access to all documents due to its simple navigation as well as automated access authorisation to the Kawin design programme and product configurator.

Bring Vasco into your home

As part of its digitisation strategy, Vasco launched a new landing page in 2020 that combines all digital tools: an inspiration app with augmented reality, a product configurator, a specialist partner search, and an online shop for spare parts.

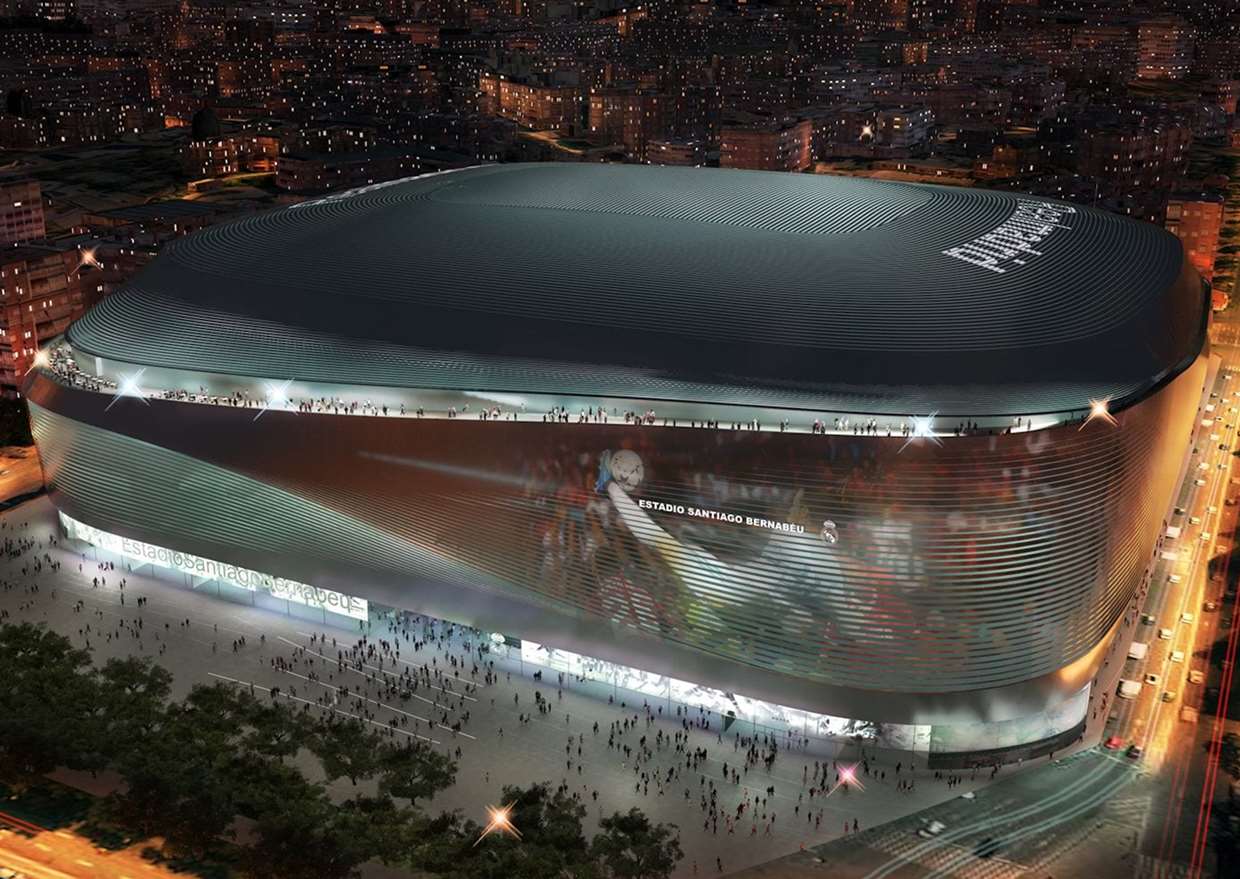

Ventilation units for the new Real Madrid football stadium

The "SABIANA ENY SP PRO" and "RCE" ventilation units from Tecna have been installed in the offices, VIP areas, and commentary booths of Real Madrid's new football stadium (ES) to improve indoor air quality.