Sustainable business strategy and market orientation

In 2021, Arbonia sold the Windows Division and integrated the Sanitary Equipment Division into the Doors Division. Since then, the product portfolio has been divided between the Heating, Ventilation and Air Conditioning (HVAC) Division and the Doors Division. In both divisions, Arbonia has been pushing the sale of projects that contribute to sustainability. Important criteria for this are energy efficiency, conserving the environment and increasing the safety for users. In addition to these general guidelines, we are pursuing quantitative goals, such as for reducing CO2 emissions in the production as well as in the application of products.

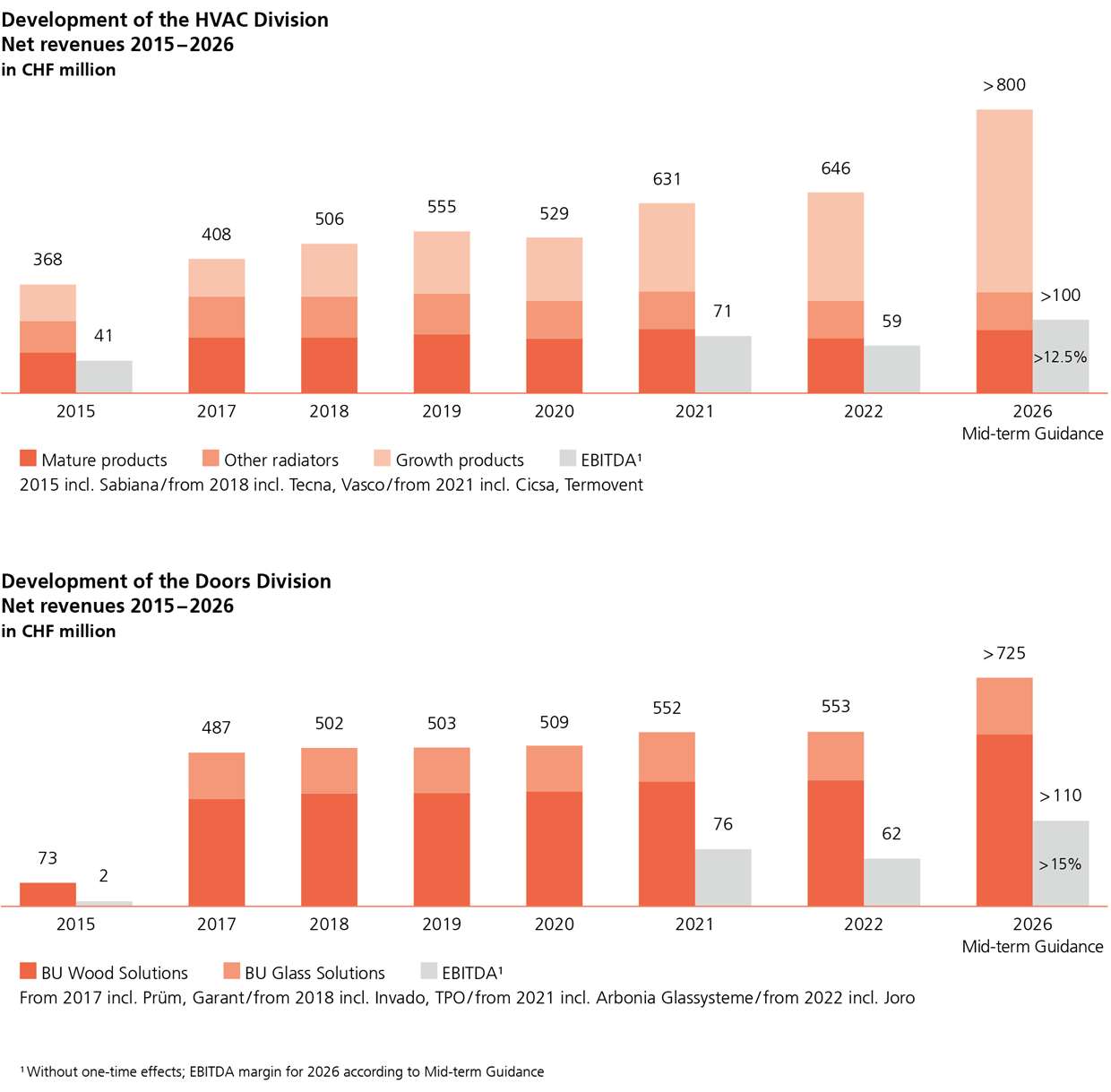

Heating, Ventilation and Air Conditioning Division

The strategy of the HVAC Division is clearly oriented towards the relevant megatrends "CO2 reduction" and "health and comfortable indoor climate". In regard to the development of the product portfolio, the focus is on growth products while simultaneously expanding the strong position in the original product groups. In the reporting year, it was possible to make targeted investments to reinforce the strategy for products and production that is based on the following four pillars:

- "Best in class" products for radiators

- Use of renewable energies with the heat pump and storage battery products

- Radiant heating and cooling for modern buildings

- Ventilation and indoor air quality

The strategy of the HVAC Division is oriented towards the climate change package of the EU Commission, which aims to reduce greenhouse gases by 55% by 2030 and a climate-neutral economic area by 2050. The division has already been pursuing a consistent strategy of further developing integrated heating systems and corresponding components with innovations for many years. This product strategy comprises modern heat generation and optimum heat transfer as well as energy storage systems for all building types and application areas. At the same time, Arbonia offers solutions for new buildings as well as the renovation market.

The division serves the market for heat pumps, which is currently growing strongly, with its new production plant in Opočno (CZ). For 2023, it is planned to install a PV system on the roof that will supply the production systems with renewable energy.

In the reporting year, the division launched a resource-friendly, highly efficient generation of the air / water pump for the lower and middle performance range. As an addition to the heat pump range, a new warm water and buffer storage tank was launched that follows a modular structure and has a high degree of pre-assembly. In addition, the division is currently developing a storage battery based on the sustainable redox flow technology that presents a future-oriented alternative to conventional lithium-ion batteries for private as well as commercial residential construction. The series production of the storage battery was started at the Stříbro (CZ) site in the fourth quarter of 2022.

In addition to the four pillars of the strategy, the HVAC Division is optimising its production footprint further. The production plant in Tubbergen (NL) was therefore closed in order to consolidate the capacities for the production of steel panel radiators. For this purpose, the highly automated Plattling (D) site was expanded to the competence centre of the division in the area of producing steel panel radiators. To make the value-added process more productive and flexible, individual press parts are marked with a lasered, unique QR code. Further projects for reducing complexity and cutting costs have also been initiated.

Doors Division

In 2021, the Sanitary Equipment Division with its shower doors and shower partitions was integrated into the Doors Division as the Glass Solutions Business Unit. In the reporting year, joint initiatives were created, in particular for market cultivation in contract sales as well as procurement.

The Wood Solutions Business Unit is pursuing a multi-year investment programme to increase productivity and expand capacities. The overarching aim is to improve delivery performance. A large part of the investments goes into expanding the capacity of the two German door plants, Prüm and Garant. Among other things, the property of the Garant production plant was purchased. Further investments concerned a second high-bay warehouse as well as a combined heat and power (CHP) plant. For the Prüm company, a new frame plant was built that was completed in the reporting year. Arbonia also invested in a spraying robot at the RWD Schlatter company and started the construction of a raw material and finished goods warehouse at this Swiss site. After the investments that have been made, the Wood Solutions Business Unit can produce around 900 000 more doors with corresponding frames than before.

The division additionally invested in the IT and digitisation of processes. At the Invado company, the ERP system was changed over to SAP S4 / HANA in the reporting year. The SAP team is currently working on the rollout for the other companies of the division (see introductory interview in the chapter). The harmonisation of the ERP system will make the future cooperation between the companies more efficient and increase productivity.

In the reporting year, the division acquired 100% of joro Türen GmbH, a producer of special doors for protection against fire, smoke, noise and intruders with approvals and certifications for oversized doors. This adds to the industrial range of the division in order to meet more individual customer requirements. At the same time, this expands the contractor services business.