Resource efficiency

The stated goal of Arbonia is to protect natural resources. A sound resource management and waste avoidance relieves the burden on the environment while reducing material consumption and rejects at the same time. The energy- and material-efficient production on the basis of a good resource management, which extends from energy-efficient procurement of primary materials to the delivery of the products, reduces manufacturing costs and thus increases competitiveness. For this reason, Arbonia takes into account potential energy and material savings in the development of new products as well as in the further development of existing products. Waste that accrues during operation is consistently separated, pretreated where necessary, and sent to recycling. Arbonia companies regularly examine measures for using resources even more sparingly – for example, with a clever product design and a production that is as error-free as possible. To ensure a careful use of resources, in particular regarding water and waste, Arbonia also issued a water policy and a waste policy in the reporting year that are scheduled to go into effect on 1 January 2022.

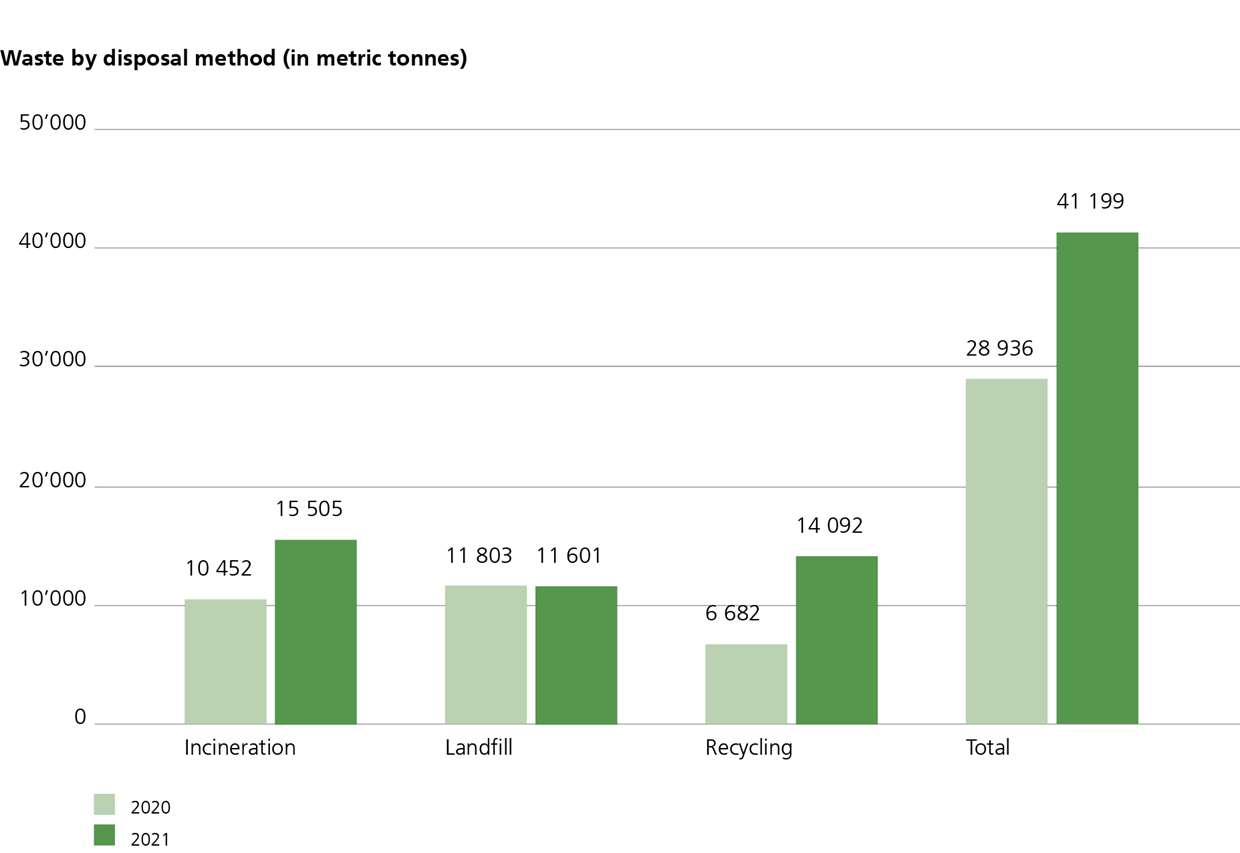

Key figures for resource efficiency

The figures for commercial and hazardous waste cover all manufacturing companies in the Arbonia Group as well as the headquarters in Arbon, Switzerland. Pure distribution companies were not included. The survey method was changed, which is why the values for 2020 and 2021 are not comparable. In future, the values will be collected consistently.

Heating, Ventilation and Air Conditioning Division

Continuous resource minimization and recycling

The HVAC Division has the goal of minimising the use of material in production. The error costs within the division are to be reduced to significantly below 1% of the annual turnover – while simultaneously increasing productivity. Furthermore, the division wants to use more recycled materials in all areas. The aim is also to reduce waste and the associated direct and indirect costs. The amount of products that are sent to waste incineration and landfills is also to be analysed and minimised. As a result, employees who have been primarily involved with waste disposal and recycling so far can now be used more for projects for increasing sustainability. Last but not least, the division also makes an important contribution to the careful use of resources with its products as well. Steel panel radiators, for example, are nearly completely recyclable and can be recycled at the end of their lifetime.

Within the division, resource efficiency is continuously monitored by, among other methods, tracking key figures for internal and external error costs, internal and supplier audits (functional cost and value analyses), or monthly reporting.

Impressive results from targeted measures

By complying with internal and external guidelines and thanks to efficient processes, it was possible to reduce the reject and error costs further in the reporting year. At Kermi, the current projects for reducing sheet thicknesses were advanced further. The greatest challenged turned out to be maintaining the required pressure stability. At the Stříbro site, the packages were optimised: Instead of foil and polystyrene, packages of reusable cardboard are now being consistently used. At Sabiana, it was possible to considerably reduce the copper scrap that occurs. A new ultrafiltration plant allows sustainable water treatment, thereby reducing water consumption. In the reporting year, the Sabiana company also started a consistent waste separation and recycling programme in offices as well as in production.

Doors Division

Minimise, recycle, optimise

In the Doors Division, the topic of resource efficiency primarily comprises minimising production waste, but also dealing with waste that occurs during operation. An efficient use of resources especially includes reducing production residues, but also an optimum configuration of transports to minimise special journeys.

Resource efficiency along the entire value-added chain

Resource efficiency is relevant to the Doors Division along the entire value-added chain. In order to optimise material consumption and avoid waste, a resource-conserving production is already aimed for in the development stage. The use of old parts or carry-over parts is also checked in this phase. The topic of resource efficiency is closely linked to product quality in the Doors Division – because high-quality products not only mean fewer rejects but also fewer complaints and thus a higher customer satisfaction. In the division, reject and error costs are to be minimised through continuous monitoring of the resource efficiency. For example, the packaging concept of Kermi Sanitär in Plattling (D) has been changed in the past years to avoid the use of polystyrene and foils as much as possible.

An efficient use of the required resources is achieved through stable, simple processes and the consistent reduction of rejects. Residues from production are recycled whenever possible. To improve resource efficiency, permanently informing and training employees is also decisive.

The topic of sustainability certification of the manufactured products is continually gaining relevance: More and more customers demand low-pollutant materials and attach importance to a certification. In addition, numerous products already undergo testing for harmful substances and are correspondingly certified according to the guidelines of the ECO Institute. To define the processes, the individual companies place great value on a close cooperation between the management and the production, maintenance, and technology departments. For example, Invado has succeeded in improving the economic efficiency and the resource efficiency of production processes by introducing the one-piece flow principle. The new process ensures considerably lower time, material, and resource costs and thus more effective production. Lean manufacturing will make it possible to increase quality and thus reduce the number of complaints to a minimum in the medium term. To achieve the overarching goal – the strengthening and expansion of its market position by providing innovative and reliable products – the division strives to continuously develop and improve its quality management systems. Improvements in manufacturing technology are just as natural as the ongoing modernisation of the machinery and a target-oriented selection of suppliers to improve the quality of raw materials. Other important factors are continuously improving personnel qualifications, involving all employees in implementing all measures, and transferring the responsibility for quality to the employees.

Ambitious targets

For the Doors Division, the inclusion of energy-specific and environmentally relevant key figures plays an important role in the planning and design of future production technology. Garant, for example, intends to reduce its energy and resource consumption per manufactured part by at least 3%. This is to be achieved through improved efficiency of the machines, preventive maintenance and servicing, optimisation of production control, and reduction of downtimes. RWD Schlatter also wants to make these processes sustainable in the future. With its state-of-the-art machinery, the company has already laid an important foundation for this. Special attention is also to be paid to a further reduction in production waste and a consistent recycling of residues. Invado has set itself the goal of supplying doors and frames exclusively in cardboard packaging in the future. This approach is currently being tested with a pilot solution for products for the French market. In addition, Invado wants to continue the principle of continuous improvement. The desired implementation of the SAP system (incl. production and detailed planning as well as production control system) is to help with the planning and tracking of production processes. Thanks to this integrated company management software, the company will be able to monitor the production more efficiently, identify the places that produce the most waste – and initiate improvement measures on the basis of this data. The companies of the division also want to reduce their inventories in order to optimise the use of resources here as well and additionally improve delivery accuracy. The targets are monitored through monthly tracking, among other things.

Successes in the reporting year

At Kermi and Bekon-Koralle, many of the desired measures could be implemented in the area of resource efficiency despite the ongoing pandemic. The commissioning of the new packaging plant at Kermi led to a significant reduction in production waste. With the use of environmentally friendly and reusable packaging materials, it was also possible to reduce the customers' disposal costs as well. Prüm, Garant, and RWD Schlatter were able to further increase their material efficiency in the reporting year. Invado introduced a procedure for monitoring and identification of faulty products to optimise manufacturing processes. This process and the initiated corrective measures have already led to a reduction in rejects.